Tenaris Bay City

Many Low Impact Development Practices were used, including bioretention, bioswales, vegetated structural roadway shoulders, permeable pavers and rainwater harvesting and reuse.

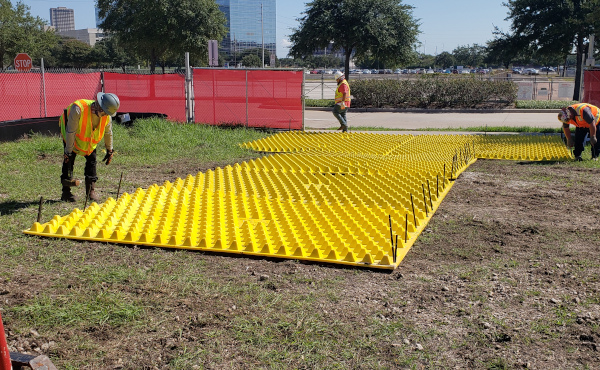

...One of the most important tools in preventing stormwater pollution from a construction site is the Stabilized Construction Exit (SCE), also referred as Stabilized Construction Access, Construction Exit, Exit, Rock Exit, etc… These can be made of various materials, the most common being rock. However, a new product called FODS is shaping up to be a great alternative to rock exits. Construction EcoServices is the Texas Distributor of FODS trackout mats and provides statewide delivery and installation services.

![]()

“Rock exits may look cost-effective at a glance, but being durable, portable and reusable, the economics of using FODS trackout mats instead is clear. “

John Moss

Director of Business Development

FODS – The Mud Stops Here

The FODS Trackout Control Mat was created as a simple solution to a common problem – construction companies were spending valuable time and money on ineffective, conventional trackout solutions like aggregate or wheel washes which still resulted in job site fines. Developed by an experienced team of contractors and engineers, the FODS Trackout Control Mats is the only durable, cost-saving, and environmentally friendly trackout solution available. FODS Trackout Control Mat was created…TO STOP MUD IN ITS TRACKS!

Construction EcoServices is the Texas Distributor of FODS and we provide statewide delivery and installation services. Use the button to the right to get a quick quote from us. We’ll also help you determine the amount of mats your jobsite will require.

FODS stands for Foreign Object Debris System.

The purpose and design of the FODS Trackout Control Mats are to effectively remove sediment from vehicle tires as they exit a disturbed land area onto a paved street.

The FODS Trackout Control Mats help sediment control by deforming the tire, spreading the tire lugs apart, depositing the dirt, rock, mud, or other sediment onto the mat. Tire lugs and/or treads will make contact differently with the pyramids’ various surfaces. As the tires roll across the mat, the pyramids will scrape, clean, deform, and wipe debris from the tires. Once the tires reach the street, they will be virtually clean from any material.

FODS mats are 12′ wide x 7′ long and are 430lbs. The mats are easily stackable and will not exceed the width requirements for highway transportation.

Construction Sites, Airports, State and Local Governments, Agriculture, Forestry Access road, Oil/Gas, Energy, Telecommunication, and Mining are all in need of the FODS Trackout Control System every day.

FODS Trackout Control Mats can handle nearly limitless weight. Due to its construction from Ultra-high-molecular-weight polyethylene (UHMWPE) each pyramid on the FODS mat has a crush rating of over 50,000lbs. The smallest passenger vehicle tire will disburse it weight across a minimum of four pyramids at all times and the larger tires of a commercial vehicles with a rating of HS-20 will disburse their weight over a minimum of eight pyramids per tire. FODS has proven performance with over 250,000lbs. on a single mat.

The FODS mats are transported to the construction site on a large truck or trailer. The mats will then be off loaded into place with a forklift or truck mounted boom or jib crane on the in situ soils. No excavation or disturbance of the existing soil is necessary. Once the mats are correctly situated in place, soil anchors can be installed through the mats to hold them into place. The Cable Earth Anchor or Form Stake can be manually torqued through pre-drilled holes in the FODS mat. We recommend providing a minimum of two anchors per mat.

We recommend using a Skid-steer broom attachment or a FODS Shovel (specifically designed to scoop between pyramids). Other options include a Street Sweeper (requires adjusted bristle head), Pressure Washer (must have ability to contain water), or a Water Truck (must have ability to contain water).

Many Low Impact Development Practices were used, including bioretention, bioswales, vegetated structural roadway shoulders, permeable pavers and rainwater harvesting and reuse.

...The LID solution nearly eliminate a detention pond and in the process gained three additional lots, or 15% more homes

...Fire Department looks to the Construction EcoServices and Jacobs Engineering team to renovate their detention pond and bring it back to fully operational status.

...It was the flood water forces resulting from Hurricane Harvey that damaged both the hillside and building to the extent that the building needed to be closed.

...Many Low Impact Development Practices were used, including bioretention, bioswales, vegetated structural roadway shoulders, permeable pavers and rainwater harvesting and reuse.

...The LID solution nearly eliminate a detention pond and in the process gained three additional lots, or 15% more homes

...Fire Department looks to the Construction EcoServices and Jacobs Engineering team to renovate their detention pond and bring it back to fully operational status.

...It was the flood water forces resulting from Hurricane Harvey that damaged both the hillside and building to the extent that the building needed to be closed.

...Maintaining a construction exit consist of “turning” the rock and or simply adding additional rock which we call a refresh. Either one will be required once the rock exit has accumulated a substantial amount of sediment that causes tracking to occur onto the street as depicted above.

If your site does not meet the spec and or the amount of rock is minimal, odds are your site might be visited or you may need additional rock more often. Thus increasing what you thought was a cheaper price for an exit.

Ask the questions – what size will my SCE be? What size rock do you use? How much rock will you lay down? Be careful of someone giving square yardage, this can be deceiving. How deep will the SCE be and do you lay a fabric down first? So goes the saying, Buyer Be Ware.

If you have any questions regarding Stabilized Construction Exits or requirements for staying in compliance, contact us. We are here to help.

They are the first call I make when I need cutting edge information on green infrastructure implementation options and resources and they have always been willing and able to help.

WT Byler trusts the knowledge and expertise of Construction EcoServices for Stormwater Compliance on our projects.

I believe I started using your firm back in 2004/05, and haven’t ever regretted that decision.

ECO is well organized, detailed-oriented and has remarkable responsiveness when service requests are needed. In all our diversity we depend highly on. ECO to maintain their responsibilities they have become one of our most valuable and dependable assets of our organization for over eight consecutive years.

They are the first call I make when I need cutting edge information on green infrastructure implementation options and resources and they have always been willing and able to help.

WT Byler trusts the knowledge and expertise of Construction EcoServices for Stormwater Compliance on our projects.

I believe I started using your firm back in 2004/05, and haven’t ever regretted that decision.

ECO is well organized, detailed-oriented and has remarkable responsiveness when service requests are needed. In all our diversity we depend highly on. ECO to maintain their responsibilities they have become one of our most valuable and dependable assets of our organization for over eight consecutive years.