Green Infrastructure Performance Liability for Contractors and Designers

A major hurdle for a stormwater designer is ensuring the performance of the system after it’s been constructed. It doesn’t matter how good the design looks on paper, if it’s not constructed properly and within specification, the system is bound to clog or fail. In the 16 years that Construction EcoServices (CES) has been in business, we have seen this happen all too often, sometimes at the expense of the design firm or the end user. Those opportunities gave us the chance to learn how to prevent failure and ensure performance. We learned that stormwater management systems for GI need performance criteria, they help establish liability during construction. On a recent project in North Texas, the use of performance specifications prevented the premature failure of a newly installed bioretention system.

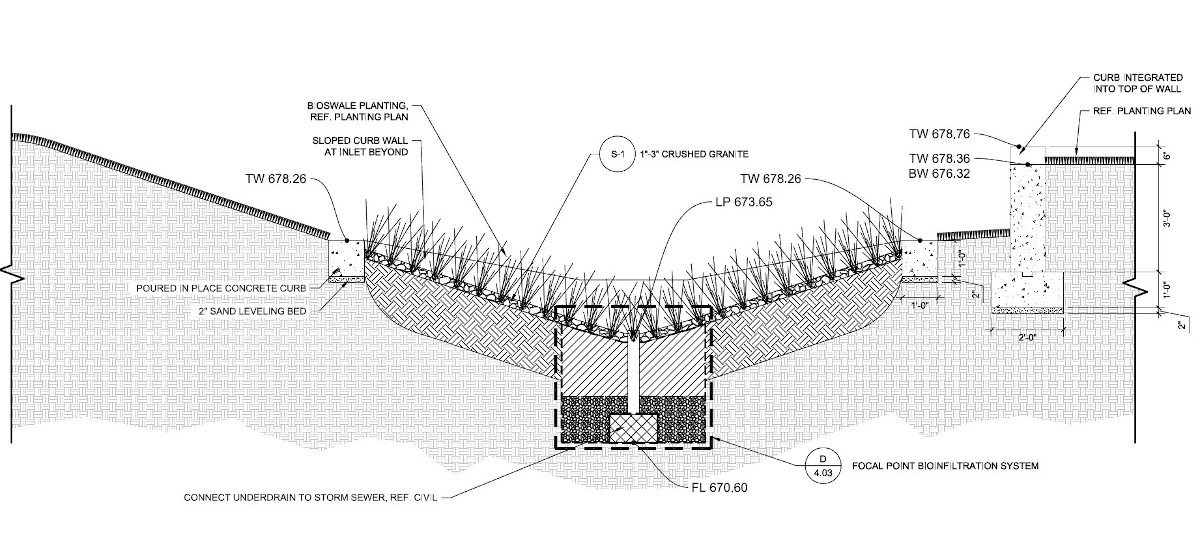

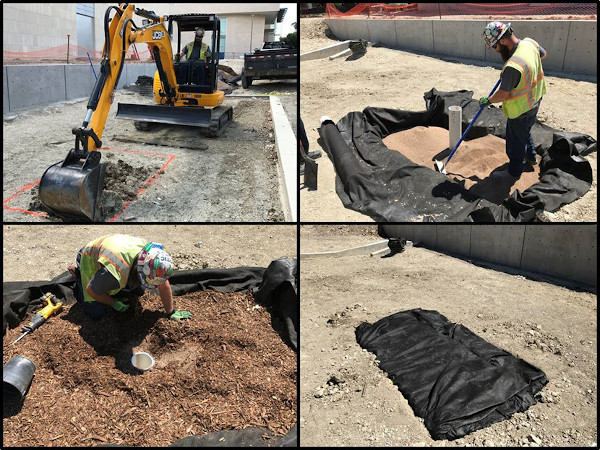

Before the bioretention and surrounding area was landscaped, CES installed the high flow biofiltration system. As you can see in the photos the threat of sediment pollution was likely during the next rain event. We prevented premature failure with a cap &seal, a simple geotextile cap envelope that wraps the entire system. The cap & seal remains until the site is stabilized, at that point the system can be planted. The FocalPoint installation took less than a day and the remaining area was planted and crushed granite was added.

Before the bioretention and surrounding area was landscaped, CES installed the high flow biofiltration system. As you can see in the photos the threat of sediment pollution was likely during the next rain event. We prevented premature failure with a cap &seal, a simple geotextile cap envelope that wraps the entire system. The cap & seal remains until the site is stabilized, at that point the system can be planted. The FocalPoint installation took less than a day and the remaining area was planted and crushed granite was added.

Just like any other construction project, communication can take a back seat to project deadlines. When the bioretention area was landscaped, the biofiltration system never got activated. This meant the cap & seal was still intact, preventing stormwater from infiltrating into the underdrain. It didn’t take long for a problem to arise after the first rain event. The entire bioretention system turned into a duck pond, threatening the plants and potentially clogging the rooftop drains.

Just like any other construction project, communication can take a back seat to project deadlines. When the bioretention area was landscaped, the biofiltration system never got activated. This meant the cap & seal was still intact, preventing stormwater from infiltrating into the underdrain. It didn’t take long for a problem to arise after the first rain event. The entire bioretention system turned into a duck pond, threatening the plants and potentially clogging the rooftop drains.

The FocalPoint specification required a hydraulic conductivity test after construction, which is a simple pass/fail test. It demonstrates to the designer and end user that the engineered soil is performing like it was intended to, infiltrating at 100 in/hr. In order for this system to meet that specification, the cap &seal was removed and fresh layer of mulch was added.

The FocalPoint specification required a hydraulic conductivity test after construction, which is a simple pass/fail test. It demonstrates to the designer and end user that the engineered soil is performing like it was intended to, infiltrating at 100 in/hr. In order for this system to meet that specification, the cap &seal was removed and fresh layer of mulch was added.

Once the FocalPoint was planted, CES returned to test the infiltration rate of the engineered soils and the system passed. The performance driven specifications gave the designer leverage over the contractor to demonstrate performance. Not only is the performance of the system guaranteed, but the first year’s maintenance is provided by the installer. This gives the end user assurance that they aren’t left alone trying to figure out maintenance on their own. If there wasn’t a clear performance specification, it would have been much easier to pass the blame around. In this situation the designer was able to reduce their liability and deliver a high performance solution to their client.

Green Infrastructure (GI) design and construction is much different now than it was 10-15 years ago. Designers and owners are learning about the liability they are exposed to with bioretention and permeable pavement systems. Below is a list of challenges that designers can overcome during the design phase with performance driven specifications:

Green Infrastructure (GI) design and construction is much different now than it was 10-15 years ago. Designers and owners are learning about the liability they are exposed to with bioretention and permeable pavement systems. Below is a list of challenges that designers can overcome during the design phase with performance driven specifications:

- GI systems are prone to clogging during construction

- End users are not educated on long-term maintenance and performance

- Contractors have a steep learning curve to overcome

- When something goes wrong, everyone starts pointing fingers to shift blame

Want to learn more about stormwater management systems? Check out our other posts on the stormwater blog or you can request a lunch & learn.