WHY THESE PRODUCTS?

CENTRALIZED

Centralized treatment options are the standard in stormwater quality management, but there are a number of different ways to accomplish this treatment model. Whether you use an in-line system and treat the entire flow or an off-line system and only treat the first flush has a lot to do with what standard of treatment you are trying to uphold and what your expectations of short term and long term costs are. Our approach at Construction EcoServices is to look at the site in its entirety and find out what design strategy best fits the end user. Questions like “How long do you anticipate owning the property” and “How many outfalls and inlets will the property have” are critical in determining what the best course of action is. Where a client, such as Halliburton, FMC Technologies or Phillips 66, might plan on owning a facility for over 10 years, an inline system might better fit their needs as maintenance intervals are longer and cost of ownership is less. If you are a retail developer that are looking to build and sell the property, an off line system might make more sense because the upfront construction costs are less. Either way, Construction EcoServices has the expertise and products to fit your client’s needs.

DECENTRALIZED

Decentralized treatment options are the basis of Low Impact Development, but can also be utilized in a traditional stormwater management regime. Treating water where it falls can greatly improve the economics of your stormwater quality management plan on site. Our approach at Construction EcoServices is to look at the site in its entirety and find out what design strategy best fits the end user. Questions like “How long do you anticipate owning the property” and “How many outfalls and inlets will the property have” are critical in determining what the best course of action is. Where less than 15 inlets are on a site or there are multiple outfalls, often times a decentralized approach will save your client in both upfront costs and long-term maintenance costs.

Our Decentralized Treatment Products

First Defense® High Capacity

Versatile Stormwater Separator

Capture and retain stormwater sediment, trash and floatables in a unit that saves site space and adapts to smaller or logistically difficult site locations.

First Defense® is a versatile stormwater separator with the highest approved flow rates in the United States, enabling engineers and contractors to save site space and projects costs by using the smallest possible footprint. It also works with single and multiple inlet pipes and inlet grates. It is easily maintained from the surface by standard vacuum tanker.

Designed with site flexibility in mind, the First Defense® stormwater separator provides versatile capture of sediments, trash and floatables that allows engineers to maximize available site space without compromising stormwater treatment level.

First Defense® works easily with single or multiple inlet pipes and inlet grates, and is independently tested, verified and approved.

Targeted Pollutants

- Coarse particles

- Fine particles

- Trash

- Floatables

Applications

The First Defense® reliably treats runoff from impermeable surfaces across a broad range of catchments.

First Defense® also operates successfully as part of a management train alongside other proprietary or natural drainage features, for example as treatment before infiltration.

- As part of LID or LEED systems and Sustainable Drainage Systems (SuDS).

- Stormwater treatment at the point of entry into the drainage line.

- Sites constrained by space, topography or drainage profiles with limited slope and depth of cover.

- Retrofit installations where stormwater treatment is placed on or tied into an existing storm drain system.

- Pretreatment for filters, infiltration and storage.

BENEFITS

Cuts Footprint Size and Cuts Costs

The First Defense® provides space-saving, easy-to-install surface water treatment in standard sized chambers/manholes.

Adapts to Site Limitations

Variable configurations will help you effectively slip First Defense® into a tight spot. It also works well with large pipes, multiple inlet pipes and inlet grates.

Prevents Washout

The First Defense® retains the pollutants it captures. The low-energy vortex separation of the First Defense® eliminates excessive agitation of captured pollutants ensuring that these pollutants are not washed out during subsequent rainfall events.

Saves Installation Time

Every First Defense® unit is delivered to site pre-assembled and ready for installation – so installation is as easy as fitting any chamber/manhole.

$1000 Special Offer

Our products partner, Hydro International, is offering our contractor friends a great offer, automatically save $1000 off your next water quality structure by using a First Defense® High Capacity hydrodynamic separator (FDHC) instead of an alternative separator. If you think the FDHC is a separator that you can use on one of your projects, take advantage now of the $1000 savings by contacting us today.

SUPPORT MATERIAL

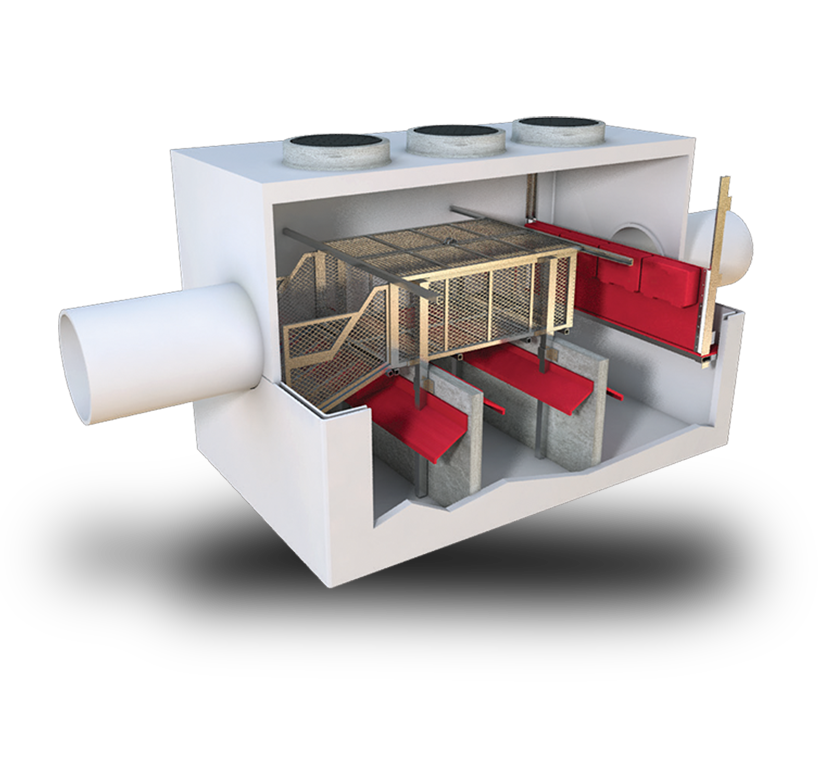

Nutrient Separating Baffle Box® (NSBB™)

Advanced Stormwater Runoff Treatment System

Why Do We Recommend This Product?

“As a product specialist, I always want to use the most efficient and effective products, which is why I always use The Nutrient Separating Baffle Box® (NSBB™). They’re easy to install, maintain long-term, and are designed to maximize available site space without compromising performance.”

Eli Gonzalez

Stormwater Quality Product Specialist, Stormwater Systems

The Nutrient Separating Baffle Box® (NSBB™) is an advanced multi stage stormwater runoff treatment system. The patented screen system is designed to capture and store debris in a dry state to minimize nutrient leaching, allowing for easier maintenance. The triple chamber design enables a high level removal of TSS over a range of particle sizes and is effective in capturing both nutrients and hydrocarbons. A patented deflector system ensures no sediment scouring occurs during high flows, allowing for online installation without needing separate diversion structures. With the addition of a SkimBoss® MAX or Floating Skimmer, the NSBB™ can further amplify the effects of the already included Hydro-Variant Technology®, bolstering pollutant capture potential, detention time and balancing conveyance with flow rate. The NSBB™ is a widely accepted treatment solution among civil engineers, developers and municipalities.

- Filtering is provided by the screen system basket, suspended above static water level, which has a capacity of several cubic yards depending on the model. The function of the screen basket is to capture gross solids like trash, foliage and debris.

- Sediment separation is facilitated by three settling chambers with a capacity of several cubic yards each depending on the model. These chambers collect smaller sediments and particulate metals.

- StormBooms™ attached to the influent side of the skimmer remove floating and emulsified hydrocarbons from the water.

NSBB Sizing Chart |

||||||

|---|---|---|---|---|---|---|

| NSBB Model # | Pipe Size | Interior Width | Interior Length | Baffle Height | Interior Height | |

|

Standard

|

Lite

|

|||||

| 2-4-60 | 4″ to 12″ | 12″ to 15″ | 2′ | 4′ | 24″ | 5′ |

| 3-6-72 | 8″ to 18″ | 18″ to 24″ | 3′ | 6′ | 36″ | 6′ |

| 4-8-84 | 12″ to 18″ | 18″ to 30″ | 4′ | 8′ | 36″ | 7′ |

| 5-10-84 | 12″ to 30″ | 30″ to 42″ | 5′ | 10′ | 36″ | 7′ |

| 6-12-84 | 18″ to 36″ | 36″ to 48″ | 6′ | 12′ | 36″ | 7′ |

| 8-12-84 | 30″ to 48″ | 48″ to 60″ | 8′ | 12′ | 36″ | 7′ |

| 8-14-100 | 36″ to 54″ | 48″ to 60″ | 8′ | 14′ | 40″ | 8′ 4″ |

| 10-14-96 | 42″ to 60″ | 60″ to 72″ | 10′ | 14′ | 40″ | 8′ 4″ |

| 10-16-125 | 48″ to 60″ | 60″ to 72″ | 10′ | 16′ | 46″ | 10′ 5″ |

| 12-20-132 | 54″ to 72″ | 12′ | 20′ | 48″ | 11′ | |

SUPPORT MATERIAL

BENEFITS

- Fits within existing easements

- Retrofits existing watersheds

- Patented screens maximize storage and prevent debris loss

- Rainwater harvesting and wet or dry detention

- Dry state storage separates debris from water and sediment

- Water will not turn septic

- Easy vacuum truck servicing

- Full capture for trash TMDL’s

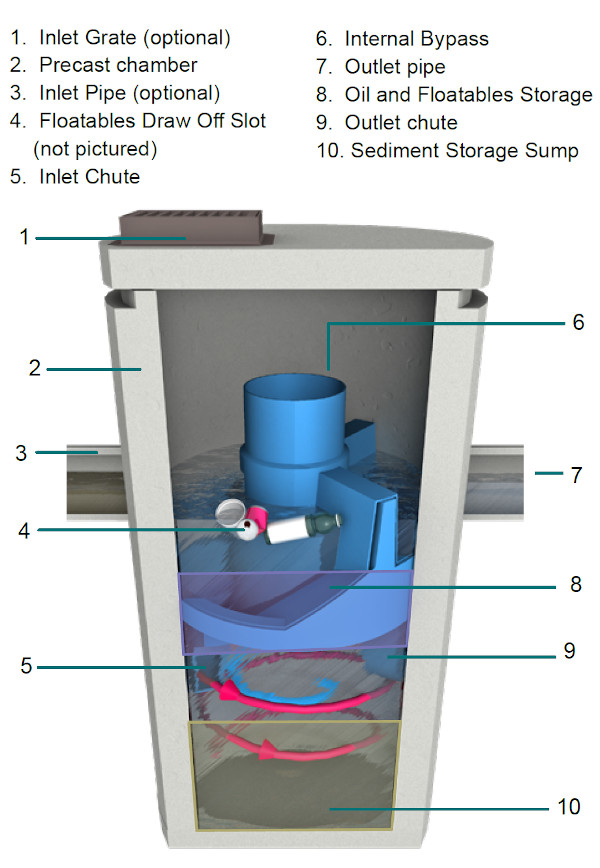

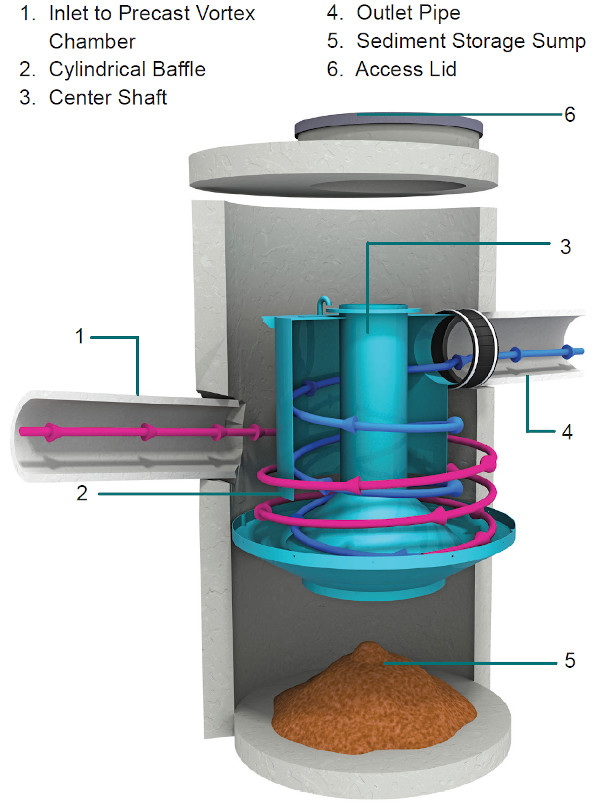

Downstream Defender®

Advanced Hydrodynamic Vortex Separator

Capture and retain sediment, oils and floatables from stormwater runoff over a wide range of flows in a small footprint.

The Downstream Defender® is an advanced hydrodynamic vortex separator that provides impressive and reliable removal of fine and coarse particles, hydrocarbons and floatable debris from surface water runoff, delivering high levels of stormwater treatment over a wide range of flow rates.

A compact, low-maintenance stormwater treatment BMP, the Downstream Defender® enables engineers to deliver effective pollutant removal at a single point in the drainage system.

Available in a range of sizes, it can function as either pretreatment or as a stand-alone device, providing engineers and contractors with a flexible, cost-effective stormwater management option.

Targeted Pollutants:

- Fine and coarse particles / total suspended solids (TSS)

- Floatable trash and debris – now available with 5mm screen to meet 100% trash capture TMDL

- Liquid- and sediment-bound oils and hydrocarbons

- Sediment-bound heavy metals

- Sediment-bound nutrients

Applications:

The Downstream Defender® reliably treats surface water runoff from impermeable surfaces including highways, car parks, industrial areas and urban developments

- As part of green infrastructure, LID or LEED systems

- Areas where high solids and trash capture are a must

- Control of silting upstream of wetlands, ponds and basins

- Industrial stormwater pollution control

BENEFITS

Adaptable

The Downstream Defender® can accommodate a change in outlet pipe direction to suit site-specific requirements.

Cuts Headloss

Low headloss means more site flexibility and provides engineers with design options for shallower sites.

Saves Space and Money

Downstream Defender® can treat high peak flows in as little as half of the footprint of other structural BMP systems. A smaller footprint means an easier install that’s less expensive and requires less work.

The Downstream Defender® is proven to prevent washout of captured pollutants. Carefully designed internal components isolate the pollution storage areas, ensuring that what is captured is retained, even during high flows.

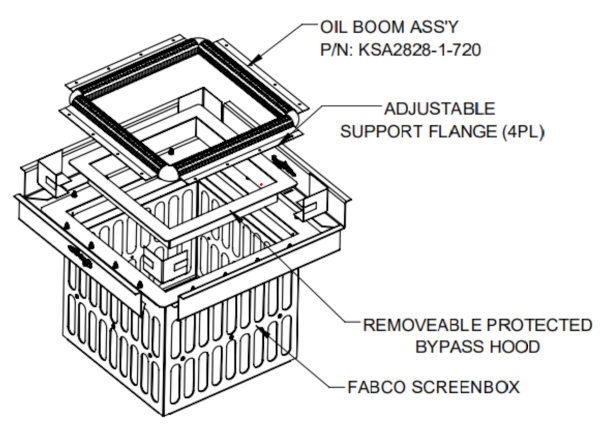

Fabco StormScreen ISB

Inlet Filter Specifically for Catch Basins

Why Do We Recommend This Product?

“Fabco’s StormScreen ISB’s are both easy to maintain and easy to install. They typically only have to be cleaned out once a year, while other “equivalent” products (typically made of mesh) need to be cleaned far more frequently. In addition, all things being equal, Fabco StormScreen ISB’s will outlast any other solution.”

Stephen Thomson

Senior Manager, Post Construction Compliance

About the Fabco StormScreen ISB

The Fabco StormScreen ISB is a retrofit filter insert designed for installation into new and existing storm drain inlets or catch basin inserts. It is a new addition to the industry leading line of catch basin insert products manufactured by Fabco.

The design traps sediment and debris, all while allowing runoff water to pass through the filter and exit through the storm drain system. The Screenbox can be used for many typical applications, such as parking lots, commercial properties, roadway surfaces as well as stormwater “hot spots,” such as transportation centers, vehicle maintenance facilities, gas stations/fueling locations and industrial applications.

The StormScreen ISB frame is manufactured from high strength 5000 series aluminum to resist cracking, abrasion, and to survive severe temperature swings. The StormScreen ISB also includes quality stainless steel wire screens and an adjustable mounting system that allows you to extend or contract the support flanges to adapt to the actual site conditions.

When stormwater enters the Fabco StormScreen ISB, it passes through and over an optional oil boom that is placed around the top perimeter of the box. After this initial pretreatment, the water flows down through the protected bypass hood into the lower filtration chamber.

As the water drops down into the chamber and is filtered through the screens, the sediment and debris collected is stored in a dry state. This reduces potential septic conditions while minimizing the material weight that must be removed during clean outs – saving space and disposal costs.

After many storm events, the collected debris can weigh up to several hundreds of pounds. Clean outs can be done manually by lifting the entire unit from the drain and dumping or more rapidly by using a commercial vacuum truck.

BENEFITS

- Optimized filtration: multiple sieve size screens enhance filtration

- Built strong: fiberglass and stainless steel construction

- Full capture for trash TMDL’s

- Bypass openings prevent clogging issues

- Will not impede inlet flow

- No need for confined space entry

- Removes more than 80% TSS

- Easy vacuum truck servicing

SUPPORT MATERIAL

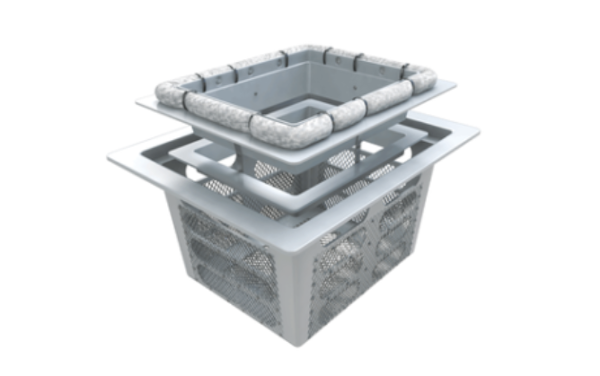

Grate Inlet Skimmer Box™ (GISB™)

Inlet Filter Specifically for Grated Catch Basins

About the Grate Inlet Skimmer Box™

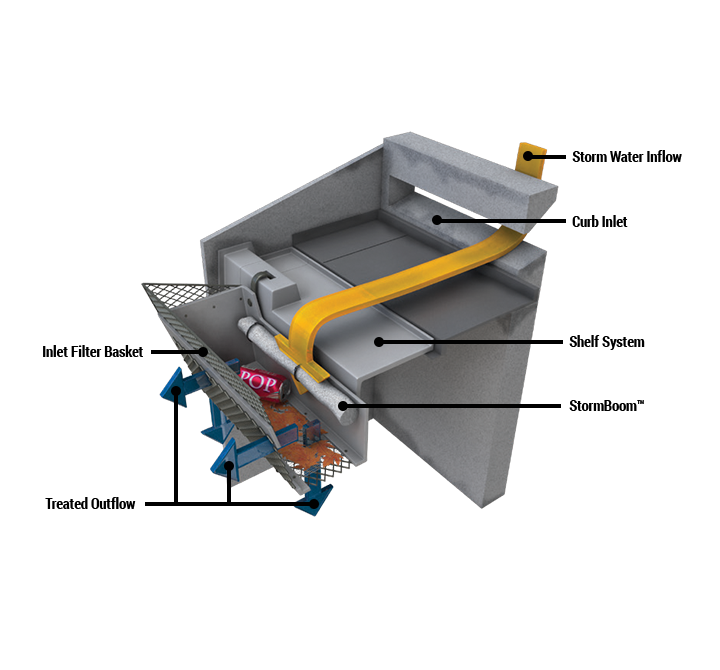

The Grate Inlet Skimmer Box™ (GISB™) is a specialized inlet filter specifically for use in grated catch basins. The unit is made of marine grade fiberglass and stainless steel to ensure longevity and durability. During a storm event, all incoming runoff passes through the internal skimmer tray and into contact with a Stormboom™. Stormwater and solid material then fall into the lower section of the skimmer box where small sieve sized filters capture and retain all solids. Turbulence deflectors within the filtration box act to calm the water and allow for a greater removal efficiency. Purified stormwater passes through the catch basin allowing the filtered materials to dry after each storm.

Highlights:

- Durable UV coated fiberglass body with stainless steel filter screens. Engineered to be a permanent component of the infrastructure.

- Multiple sieve size screens result in efficient pollutant removal without the need for bag or cartridge filters.

- Non scouring design: turbulence deflectors calm rushing water inside the filter screen system to prevent sediment scouring.

- Servicing is quick and simple via vacuum truck with no risk or damage to screens.

BENEFITS

- Optimized filtration: multiple sieve size screens enhance filtration

- Built strong: fiberglass and stainless steel construction

- Full capture for trash TMDL’s

- Bypass openings prevent clogging issues

- Will not impede inlet flow

- No need for confined space entry

- Removes more than 80% TSS

- Easy vacuum truck servicing

SUPPORT MATERIAL

Fabco Beehive Filter

Rain Garden Beehive Filter Basket

About the Beehive

Most rain gardens are designed to only capture the first inch of rain. So in any rain garden design, some type of overflow mechanism should be considered in order to prevent erosion and other potential damage from flooding.

Most rain gardens are designed to only capture the first inch of rain. So in any rain garden design, some type of overflow mechanism should be considered in order to prevent erosion and other potential damage from flooding.

Installing an overflow riser pipe and discharge pipe is a simple solution. However, the system needs to be protected from coarse floatables (such as mulch, organic materials and trash) that could lead to clogging and possibly flooding.

Beehive (or Rain Garden overflow) filter is the perfect solution for this application. It can be added to capture floatables and solids in any type of round bypass infrastructure.

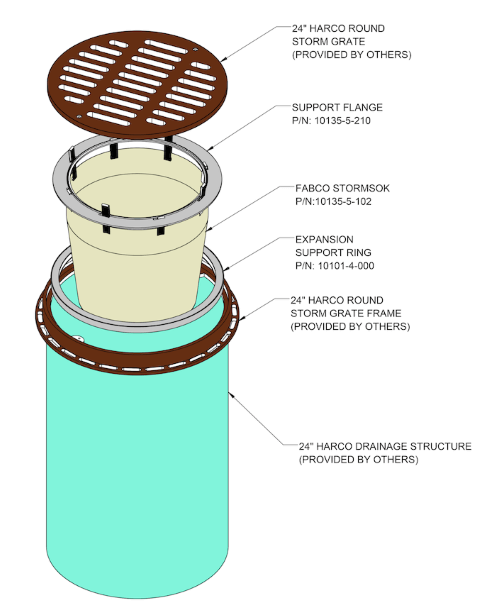

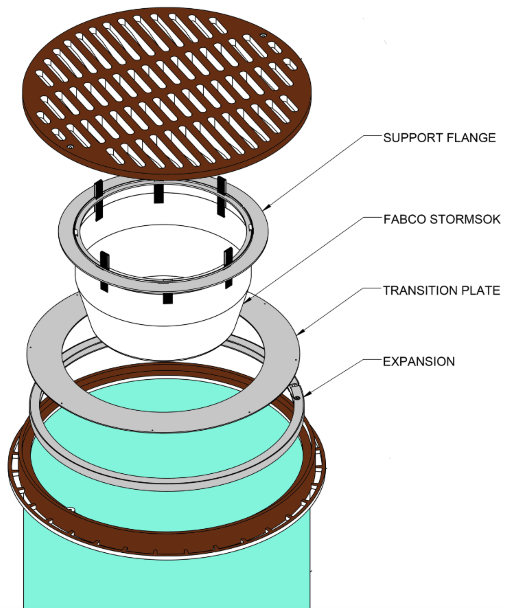

Key Elements:

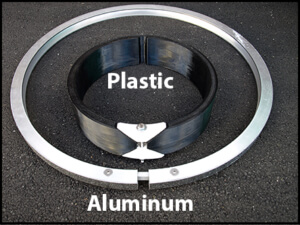

- An expansion ring (plastic or aluminum) which is sized to fit inside the riser pipe

- Geotextile filter bag with a mounting frame, and a support ring which connects the filter bag to the flange

Simple Installation:

- Insert the properly sized expansion ring into the riser pipe to the desired depth and clamp the ring firmly into position

- Place the assembled filter bag on top of the expansion ring

- Put the beehive grate or flat grate back on top of the riser

BENEFITS

- Simple, durable, corrosion resistant construction

- Sizes to fit most pipes: 8” up to 36” ID – short and long bags available

- Fast, simple installation – no worries about grate/frame compatibility

- Cost-effective protection for high flow operation

- Reduces clogs – keeps sediments and debris out of underground pipes

- Quick clean out –beehive filter lifts up and out for servicing

SUPPORT MATERIAL

Curb Inlet Basket™ (CIB™)

Inlet Debris & Sediment Filter

About the Curb Inlet Basket

The Standard Capacity Curb Inlet Basket (used in shallow catch basins) and High Capacity Curb Inlet Basket (used in deep catch basins) are specialized inlet filters used for curb inlets where the only access element is a manhole. Both units are made of UV-coated, marine-grade fiberglass and stainless steel to ensure longevity and durability. Both inlet filters are unique for their shelf system which directs storm water flow into the filter positioned directly under the access manhole. This system can be manufactured to any size and style of catch basin. The Standard Curb Inlet Basket and High Capacity Curb Inlet Basket are multi-stage filtration systems that can capture a variety of pollutants and debris during a storm event. Under high volume flows, water can bypass the filtration system by flowing past the filter and into the catch basin.

Operation Summary:

- Storm water carrying debris and pollutants enters through the curb inlet.

- An adjustable throat width funnels water to the weir. The immediate drop in the throat elevation prevents head loss through the inlet This allows sediment to collect along the incoming side of the weir.

- The water flows over the weir and into the filtration basket, filtering out trash, sediment and hydrocarbons.

- Filtered water leaves the basket and enters the catch basin. The position of the curb inlet basket high in the catch basin allows for captured debris to dry between storm events and avoid restriction to upstream pipes.

Highlights:

- Durable UV coated fiberglass body with stainless steel filter screens. Engineered to be part of the permanent infrastructure

- Multiple sieve size screens result in efficient pollutant removal

- Non scouring design: turbulence deflectors calm rushing water inside the filter screens to prevent scouring

- Servicing is quick and simple via vacuum truck with no risk or damage to screens

BENEFITS

- Filters stormwater entering shallow or deep curb inlets and catch basins

- Multi stage filtration captures an array of contaminates

- Built strong: fiberglass and stainless steel construction

- Easy maintenance: service via vacuum truck or manually

- Full capture for trash TMDL’s

- No need for confined space entry

SUPPORT MATERIAL

Rain Guardian

Pretreatment Debris Filter

About Rain Guardian

Rain Guardians were developed by the Anoka Conservation District to extend the maintenance cycles of their bioretention facilities while simplifying the maintenance process. Where tradition forms a pre-treatment like forebays and grass filter strip have to be completely removed and replaced during regular maintenance, the Rain Guardian can be cleaned and ready to go in just minutes.

BENEFITS

- Optimized filtration: multiple sieve size screens enhance filtration

- Built strong: fiberglass and stainless steel construction

- Full capture for trash TMDL’s

- Bypass openings prevent clogging issues

- Will not impede inlet flow

- No need for confined space entry

- Removes more than 80% TSS

- Easy vacuum truck servicing

SUPPORT MATERIAL

Fabco Connector Pipe Screen

Catch Basic Insert Filter

About the Connector Pipe Screen

A Connector Pipe Screen (CPS) is a catch basin insert filter that is designed to capture trash. Unlike other catch basin inserts that are typically installed closer to the inlet (under the drain grate or below the curb opening), CPS inserts are installed in front of the catch basin’s outlet pipe – trapping trash and debris inside the catch basin while allowing filtered stormwater to exit into the storm drain infrastructure.

A Connector Pipe Screen (CPS) is a catch basin insert filter that is designed to capture trash. Unlike other catch basin inserts that are typically installed closer to the inlet (under the drain grate or below the curb opening), CPS inserts are installed in front of the catch basin’s outlet pipe – trapping trash and debris inside the catch basin while allowing filtered stormwater to exit into the storm drain infrastructure.

CPS insert features:

- Manufactured from perforated, 14 gauge, 304 stainless steel sheets

- Perforations have a 5 millimeter diameter – screen has an open area greater than 50%

- CPS net open area (when converted to an equivalent pipe diameter) exceeds the actual diameter of the outlet pipe leaving the catch basin – CPS can pass more volume than the outlet pipe it covers

- Overflow / bypass prevents flooding if screen becomes blocked or covered

- The CPS is designed to cover a specific pipe diameter – its size does not depend on the size of the catch basin drain. The CPS is a compact, affordable product that is easy to install and adaptable over a wide range of catch basin sizes and styles.

- The design utilizes very little space, maximizes the trash storage capacity within the catch basin and allows for easy maintenance.

CONTACT US

SUPPORT MATERIAL

preTX

Pretreatment Debris Filter

About preTX

About preTX

Keep your biofilters, bioretention and subsurface infiltration systems clean.

PRETX is available in several different configurations, enables the simplified maintenance of green infrastructure systems at the inlet in a deep sump catch basin that is accessible and requires no specialized maintenance equipment. The absence of a pre-filter may allow sediment, trash and debris to prematurely clog the biofilter media or infiltration bed. Surface accumulation of trash and debris can require frequent maintenance for aesthetics in high loading land uses and reduce the infiltration rate of filtration media. Installation is simple and comparable to common catch basins and grates.

BENEFITS

- Optimized filtration: multiple sieve size screens enhance filtration

- Built strong: fiberglass and stainless steel construction

- Full capture for trash TMDL’s

- Bypass openings prevent clogging issues

- Will not impede inlet flow

- No need for confined space entry

- Removes more than 80% TSS

- Easy vacuum truck servicing

About preTX

About preTX